What Function is Provided by the Leadscrew on a Lathe That is Not Provided by the Feed Rod

Today we are going to discuss different parts of lathe machine which is useful for performing the operation of lathe machine.

Lathe machines are more versatile than all other machines.

It is mainly used for machining circular surfaces such as cylindrical or conical but it can also be used for making flat surfaces, drilling holes, machining slots, and many other types of work.

So without wasting time let's get started.

Parts of Lathe Machine

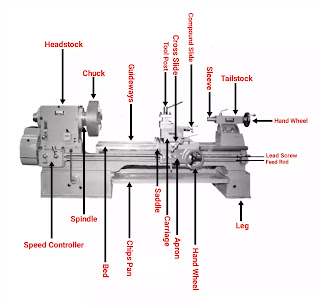

There are following parts are used in the lathe machine:

- Bed

- Guideways

- Headstock

- Spindle

- Carriage

- Saddle

- Cross slide

- Compound Rest

- Compound slide

- Tool Post

- Apron

- Tailstock

- Chuck

- Face Plate

- Center

- Feed Shaft

- Lead Screw

- Legs

- Chips Pan

- Hand Wheel

- Speed Controller

- Bull Gear

- Sleeve

Show in the figure different parts of the lathe machine which are described below in detail.

|

| Parts of Lathe Machine |

Bed

A bed is the main body of the machine.

All the main components are bolted on it.

It is usually made of cast iron due to its high compressive strength.

It is made by the casting process and is bolted to the floor space.

Its top section consists of bed guideways or 'V' ways which are precision machined and used to guide and align the other parts of the lathe.

Guideways

Guideways take care of the movement of tailstock and carriage on the bed.

Headstock

Headstocks are the main body parts that are placed on the left side of the bed.

It serves as a holding device for gear chains, spindles, driving pulleys, etc.

The mechanism of the headstock is driven by an electric motor that rotates the spindle.

It is also made of cast iron.

Spindle

It is the main part of the lathe which holds and rotates the chuck.

Threads, tapers, etc. are made at one end of the spindle to which holding devices can be attached.

Carriage

It is located between headstock and tailstock.

It is used to hold and move the tool post along the bed either towards or away from the headstock.

It slides on the guideways.

It is also made of cast iron.

It has six main parts:

- Saddle

- Cross slide

- Compound Rest

- Compound slide

- Tool Post

- Apron

Saddle

It is an 'H' shaped casting mounted on lathe ways, supports the cross slide that provides movement to the tool post.

Cross Slide

A cross slide is a part of the carriage that allows the movement of a tool post at a right angle to the bed guideways during machining.

The cross slide is moved by the feed screw.

Compound Rest

A compound rest is a part that connects the cross slide and the compound slide.

The compound rest is mounted on top of the cross slide.

It has a circular base on which the graduations in degrees are made.

Its power is not fed but it is operated by hand.

A certain depth of cut can be set by rotating the feed screw of the compound rest.

After setting it as required, the compound slide is solidly locked with the base.

Compound Slide

A compound slide is attached to the compound rest by the dovetail joint.

Compound slides are used to cut angles or tapers that cannot be cut by rotating the headstock.

Tool Post

It is bolted to the carriage on top of the compound slide.

It is used to hold the tools at the correct position with rigidity.

Apron

An apron is situated on the carriage.

It consists of all controlling and moving mechanisms of carriage.

The apron is fastened to the saddle with feed mechanisms that provide automatic feed to the carriage.

The apron hand wheel can be rotated to move the carriage by hand along with the bed of the lathe.

Tailstock

Tailstock is a casting located on the right side of the bed.

Its function is to support the loose end of the workpiece or a job while machining.

It can slide on the bed guideways and can be clamped in any position.

The tailstock has the following purposes:

- To support the loose ends of long jobs for carrying out lathe operations.

- To hold the cutting tools such as drill chucks, drills, reamers, etc.

- Turning of outer taper by an offsetting method.

Chuck

It is an important tool, which is used to hold and rotate the workpiece.

The smallest piece of workpiece can be hold in a chuck.

Faceplate

The faceplate is fixed to the lathe spindle and can be job mounted to perform the turning operation.

Center

Center is a part of lathe machine which is used to support long jobs in between headstock and tailstock to carry out a lathe operation.

A center that fits into the headstock spindle and rotates with the workpiece is called a live center.

The center which is used in the tailstock spindle and which does not rotate is called the dead center.

Feed Shaft

It is made from good quality alloy steel.

It spans the entire length of the bed and is fitted under the lead screw.

It has a "keyway" from which motions can be given to the carriage for the feed mechanism.

When the power feed is attached, it provides cross movement to the tool.

Lead Screw

It is used for thread cutting.

Lead screw is situated at the bottom side of the bed which is used to move the carriage automatically during thread cutting.

It is made from good quality alloy and is made of acme threads.

Legs

Legs are used to carry all the loads of the machine.

They are bolted on the floor which prevents vibration.

Chips Pan

Chips pan is placed lower side of the bed.

The main function of it is to carry all chips removed by the workpiece.

Hand Wheel

This is the wheel that is operated by hand to move a cross slide, carriage, tailstock, and other parts that contain a hand wheel.

Speed Controller

The speed controller is located on the headstock which controls the speed of the spindle.

Bull Gear

It is made from cast iron.

It is used for slow and fast speeds by means of a bull gear back pin and is fixed by a 'key' on the hollow spindle.

Sleeve

Sleeve fits inside tailstock which can be moved back and forth to fit or remove dead center.

Specification of Lathe

The size of the lathe is specified according to :

- Height of the centers.

- Swing

- Center distance

- Length of bed

- Maximum diameter of the bar

- Swing on carriage

So here we have to know about parts of the lathe machine.

I hope you all enjoy it.

FAQ Related for Parts of Lathe Machine

What part of the lathe is used to move the carriage automatically during thread cutting?

The part of the lathe machine which is used to move the carriage automatically during thread cutting is the lead screw.

Which part of the lathe machine has provided a power mechanism?

The feed rod is the part of the lathe machine that provided the power mechanism.

Which part of the lathe machine is composed of the following: cross slide, apron, and tool post?

Carriage is the part in lathe machine composed of the Saddle, Cross slide, Compound Rest, Compound slide, Tool Post and Apron.

What is the function of compound rest in a lathe machine?

The main function is that a certain depth of cut can be provided by rotating the feed screw of the compound rest.

What is the function of cross slide in lathe machine?

The main function of the cross slide is to cut an angle or taper that cannot be cut by rotating the headstock.

The part of the lathe machine which is used for the supporting dead end of the long machining shaft and also maintain the axial alignment of the machining shaft is called?

The part of the lathe machine which is used for the supporting dead end of the long machining shaft and also maintain the axial alignment of the machining shaft is called the dead center.

Which part of the lathe is h shaped cast iron on the bed ways?

The saddle is the part of the lathe that h shaped cast iron on the bed ways.

What is the function of the saddle in a lathe machine?

Its main function is to supports the cross slide that provides movement to the tool post.

What is the function of the lead screw in the lathe machine?

The main function of the lead screw is used to move the carriage automatically during thread cutting.

What is the function of an apron in a lathe machine?

An apron is fastened to the saddle with feed mechanisms that provide automatic feed to the carriage.

What is the function of the leg in a lathe machine?

The main function of the leg in the lathe machine is that carries the full load of the machine and transfers it to the ground. That is why it is bolted on the floor which prevents vibration.

What is the function of tailstock in a lathe machine?

Its main function is to support the loose end of the workpiece or job during machining.

Source: https://www.mechical.com/2022/01/parts-of-lathe-machine.html

0 Response to "What Function is Provided by the Leadscrew on a Lathe That is Not Provided by the Feed Rod"

Post a Comment